Supply Chain Fundamentals: Sourcing

Jun 23, 2020

6-min read

Rich Mokuolu is the Cofounder and CEO of Partsimony. He has worked on numerous critical global supply chain initiatives across various multi-billion-dollar industrial companies. Partsimony completed the STANLEY + Techstars Accelerator in 2018, and is partnering with Techstars to support hardware entrepreneurs.

People throw around the term “supply chain” when talking about Amazon’s fast delivery service or why procuring N95 masks during a global pandemic is so challenging. However, not everyone understands the scope of what a supply chain entails. This write-up aims to explore the fundamentals of supply chains and a basic overview of supply chain strategies. I’ll use a common example of a hardware product as we go along to help crystallize key concepts.

Before we dive in, it’s important to understand the five key steps/nodes in developing and selling a hardware product (e.g. a new iPhone).

5 Key Steps / Nodes in Developing and Selling a Hardware Product:

01. Engineering

Engineering teams and designers develop specifications of the product and undergo iterative development and testing to fine-tune the design before selling the product to customers.

02. Sourcing

During the iterative development process, engineers and designers may choose to make prototypes in-house or source components from distribution channels — which provide details on inventory of electronic components across distributors — or have custom components manufactured by manufacturing suppliers such as Contract Manufacturers (CMs). Sourcing components involves vetting, negotiating, and selecting a manufacturer or distributor to procure components which are not made in-house.

03. Manufacturing

This involves the actual development of the product components — an example of this is the manufacturing of the enclosure of a given product you are looking to sell (e.g. an iPhone, motorcycle, etc.).

04. Fulfillment

The fulfillment process involves shipping the product and/or component of your product to your customer or to the retail shop where your product will be sold.

05. Customer

Too often, we don’t think of customers as part of the product life cycle. However, knowing where your customer is located and how they behave is an important consideration with far-reaching implications if you don’t address it properly.

The supply chain can be defined as, “The sequence of processes involved in the production and distribution of a commodity.” From the above steps/nodes within a product life cycle, the supply chain encompasses the sourcing, manufacturing, and fulfillment processes.

To further explain the concept of supply chains, let’s take a real-world example such as the charging case of the Apple AirPods Pro. Pictured here is a breakdown of each component that goes into the charging case of an Apple AirPods Pro.

Apple AirPods Pro components, photo courtesy of iFixit, Creative Commons Attribution Noncommercial Share Alike license

As you can see in the above picture, there are many parts that comprise a charging case for the AirPods Pro — some components are custom-fabricated, others are electrical components, etc. The list of components that comprise a product is referred to as a Bill of Materials (BOM). A Bill of Materials or product structure is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing supplier.

Make Vs. Buy

If you were to construct the supply chain for the AirPods Pro charging case, you’d need to first establish your “Make” vs. “Buy” strategy based on the BOM components:

Make: Bill of Material components that are manufactured in-house

Buy: Bill of Material components that are to be sourced from third party suppliers

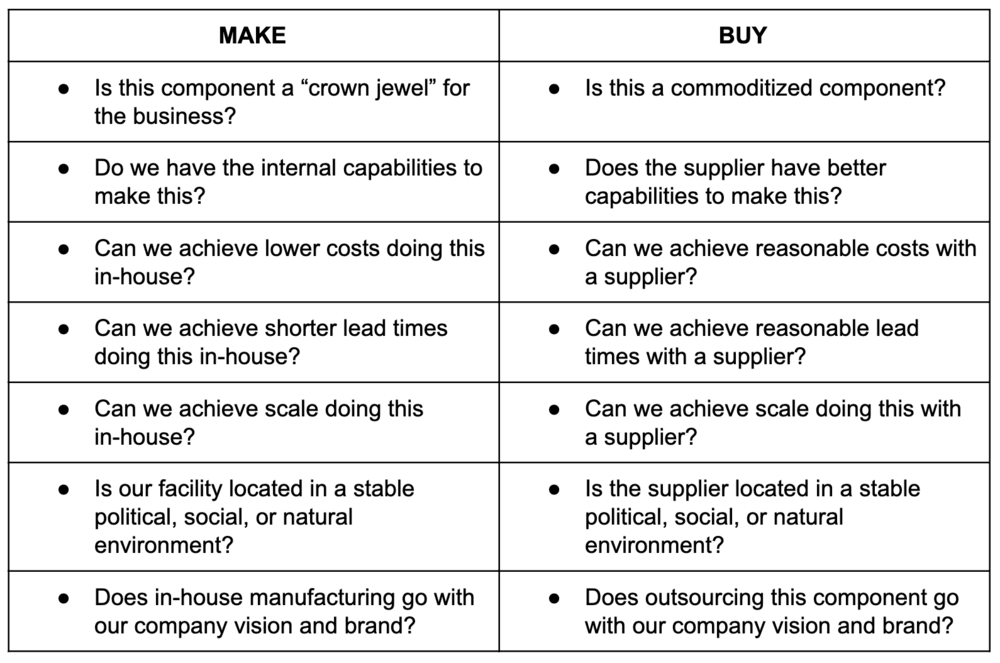

Below is a list of considerations that you can use to guide your Make vs. Buy strategy decisions.

A good rule-of-thumb is if the component in the BOM is considered a “crown jewel’ (i.e. a proprietary or key aspect to your business), it’s best to have this component made in-house or with a manufacturing partner you trust with strict contractual terms to mitigate potential risks. An example of a “crown jewel” for a hardware product is the firmware or special mechanical feature which makes the product unique.

At this point, you might be wondering how to manage your “Buy” strategy if you’re unable to make any of your BOM components in-house. Well, the answer is having a robust diversification strategy. By diversifying your supply chain, you are able to mitigate disruptions which might cripple your business (e.g. tariff wars, pandemics, etc.).

How to Determine Your “Buy” Sourcing Strategy

There are two ways to approach your “Buy” sourcing strategy:

Single-Sourced:

Having one manufacturer (e.g. a Tier 1 supplier) manufacture one or all the BOM component(s)

Multi-Sourced

Establishing multiple manufacturers to manufacture 1 or all the BOM component(s)

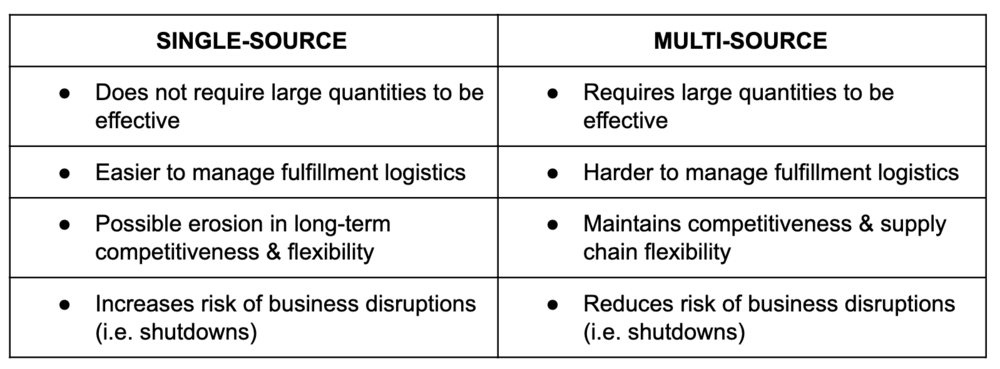

Key considerations to take into account when deciding on single-sourcing vs. multi-sourcing are listed in the below table.

A good rule-of-thumb is to aim to multi-source wherever possible. Multi-sourcing your BOM from a minimum of two to three suppliers gives your supply chain more flexibility and adaptability to changing demand and potential risks. For example, if there happens to be a significant increase in demand for your product (e.g. your product goes viral), you will be able to quickly spool up production from multiple suppliers within your network to meet the demand needs in a timely manner. Without a robust multi-source strategy, you will need to build the capacity within your established supplier network which will take precious time. A real life example of this happening is Peloton’s struggle with upstream delays amid COVID-19 pandemic demand surge for their training equipment.

Multi-tier Supply Chains

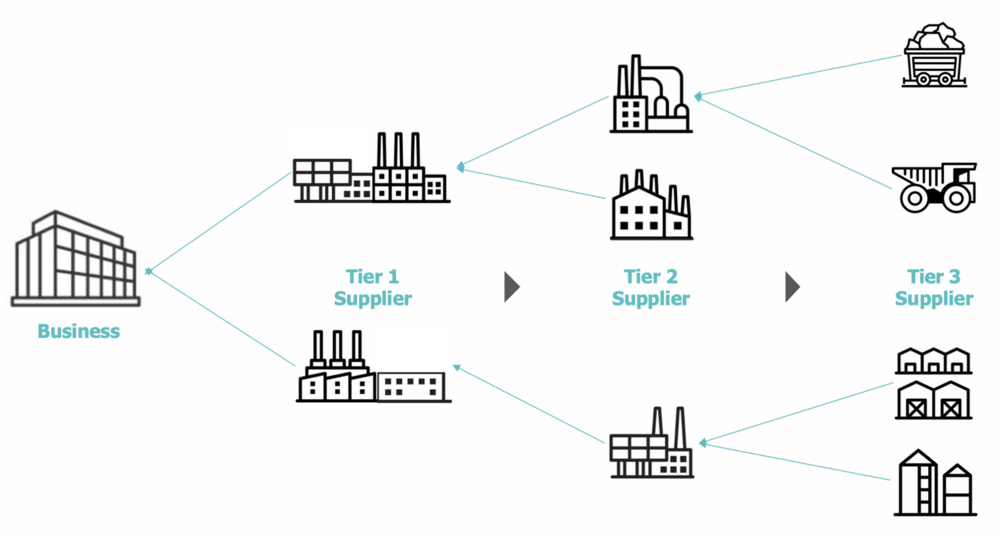

Now that we have an understanding of Make vs. Buy and sourcing diversification strategies, it’s important to understand the concept of Multi-tier Supply Chains. Suppliers can be split up into multiple levels depending on their capabilities and stage within the development process.

The above is an example of a Multi-tier Supply Chain. The further down the supply chain a supplier is, the more focused the supplier is on making a singular aspect or component of a product. To further crystalize the concept of Multi-tier Supply Chains, we’ll break out the supply chain of our Apple AirPods Pro charging case example into three tiers (as pictured above). This can be broken down as follows:

Business

This is the organization/brand selling the product (i.e. Apple).

Tier 1 Supplier

Tier 1 suppliers are typically focused on final assembly, testing, and packaging prior to sending to the business, warehouse, or retail store. For example, the manufacturer shipping assembled, tested, and packaged AirPod charging cases to Apple stores/warehouses.

Tier 2 Supplier

Tier 2 suppliers are typically focused on manufacturing components or sub-assemblies of a given product. For example, the manufacturing of custom fabricated or electronic components within the AirPod charging cases.

Tier 3 Supplier

Tier 3 suppliers are typically focused on the manufacturing of raw materials which are used by the Tier 2 supplier. For example, the manufacturing of sheet metal or plastic resin used in the fabrication of the AirPod Pro charging cases.

Supply chains are fundamental networks that impact our everyday lives from the development of our favourite devices, such as our mobile phones, to our Amazon shipments. Supply chains are the driving force that make hardware companies and global economies tick. The key competitive advantage of any business building physical products (e.g. hardware) can be determined by how strategic and dynamic their supply chain is structured — effective sourcing strategies are a very important part of competitive hardware businesses that thrive when times are tough.

In Part 2 of our “Supply Chain Fundamentals” series, we will be covering the Manufacturing segment within Supply Chain networks. Stay tuned, more to come.

Techstars partner Partsimony offers portfolio companies a 33% discount on the Partsimony platform. Partsimony will also be hosting regular mentorship sessions on important manufacturing supply chain topics.

This post was originally published on Partsimony’s blog.

Learn more about how to be a great mentor: read the Techstars Mentor Manifesto.

About the Author

Rich Mokuolu

Rich Mokuolu has worked on numerous critical global supply chain initiatives across various multi-billion-dollar industrial companies in the Aviation, Oil & Gas, Locomotive, and Renewable Energy sectors. He advises on hardware-related businesses and can be found doodling designs for new product ideas in his (non-existent) free time.